Modern Factory Control Systems: Maintenance Challenges and Smart Solutions

In today’s industrial landscape, PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems) serve as the central nervous system of manufacturing facilities. Yet many operations teams underestimate how maintenance complexities can silently erode 15-20% of annual productivity. Having implemented automation upgrades across three continents, I’ve observed that most issues stem from reactive rather than strategic maintenance approaches.

1. The Aging Infrastructure Dilemma: Beyond Hardware Obsolescence

While most focus on failing CPUs or discontinued I/O modules, the real crisis lies in the knowledge gap. I’ve encountered factories where 90s-era PLCs still run critical processes because technicians memorized ladder logic patterns that newer staff can’t decipher. Modular upgrades aren’t just about hardware – they’re opportunities to document tribal knowledge into standardized procedures.

2. Software Integration: The Hidden Bottleneck

OPC UA adoption solves only half the problem. In a recent automotive plant project, we discovered legacy HMI systems rejecting OPC tags because of timestamp formatting inconsistencies. Sometimes the fix requires building custom middleware – a solution rarely mentioned in vendor whitepapers but frequently needed in practice.

3. Predictive Maintenance: From Theory to Implementation

Power surge protection is standard, but smart factories now monitor capacitor health in power supplies. By tracking ESR (Equivalent Series Resistance) values through PLC diagnostics, we’ve predicted power module failures 3-4 weeks before catastrophic failure at multiple pharmaceutical sites.

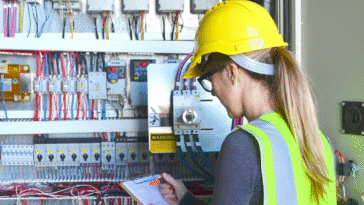

4. Troubleshooting 4.0: Augmented Reality Comes of Age

Forward-thinking plants are equipping technicians with AR glasses that overlay real-time signal status on physical components. At a German chemical plant, this reduced DCS fault diagnosis from 47 minutes to under 8 minutes average – a solution more effective than traditional training alone.

5. Cybersecurity: The Overlooked Maintenance Factor

Network segmentation often fails when contractors plug in infected USB drives during maintenance. Our layered approach includes physically separate maintenance ports with one-time authentication codes – a simple but often neglected precaution.

6. The Human Factor: Bridging the Skills Gap

Partnering with automation firms provides stopgap support, but sustainable solutions require knowledge transfer programs. We’ve had success with “shadowing systems” where legacy PLCs run parallel with new hardware during transition periods, allowing side-by-side learning.

Conclusion: Building Maintenance-Centric Automation Strategies

The most resilient factories now design control systems with maintenance requirements as primary criteria – not afterthoughts. This means selecting PLCs with built-in diagnostic LEDs, insisting on vendor commitments to 15-year support cycles, and allocating 30% of upgrade budgets specifically for knowledge preservation. The ROI becomes evident when unplanned downtime drops below 1% annually.

Check below popular items for more information in NextGen-PLC.

| Model | Title | Link |

|---|---|---|

| IC693APU305 | GE Fanuc Input Output Processor Module | Learn More |

| IC693BEM320 | I/O Link Interface Module GE Fanuc | Learn More |

| IC693ACC301 | Backup Battery GE Fanuc Emerson | Learn More |

| IC693ACC303 | Memory Card GE Fanuc Emerson | Learn More |

| IC693ACC317 | Crimp Type Connector Kit GE Fanuc | Learn More |

| IC693ACC323 | Power Supply Module GE Fanuc Emerson | Learn More |

| IC693ACC335 | Terminal Board GE Fanuc Emerson | Learn More |

| IC693ACC336 | Terminal Board GE Fanuc Emerson | Learn More |

| IC693ACC337 | GE Fanuc Emerson Interface Terminal Block | Learn More |

| 330851-02-000-080-50-01-CN | New Proximity Probe Bently Nevada | Learn More |

| 330851-02-000-060-50-00-CN | New Proximity Probe Bently Nevada | Learn More |

| 330851-02-000-030-50-00-CN | New Proximity Probe Bently Nevada | Learn More |

| 330851-02-000-050-50-00-CN | New Proximity Probe Bently Nevada | Learn More |

| 330851-02-000-040-90-00-00 | New Proximity Probe Bently Nevada | Learn More |

| 330851-02-000-080-90-01-00 | New Proximity Probe Bently Nevada | Learn More |

| 330851-02-000-080-90-00-00 | New 25 mm Probe Bently Nevada | Learn More |

| 330851-02-000-030-90-00-00 | New 25 mm Probe Bently Nevada | Learn More |

| 330851-02-000-060-90-00-00 | New 25 mm Probe Bently Nevada | Learn More |

| 330851-02-000-066-90-00-00 | New 25 mm Probe Bently Nevada | Learn More |

| 330851-02-000-070-90-00-00 | New 25 mm Probe Bently Nevada | Learn More |

| 330851-02-000-050-90-00-00 | New 25 mm Probe Bently Nevada | Learn More |

| IC695ALG106 | Isolated Analog Module GE Fanuc Emerson | Learn More |

| IC695ALG112 | Isolated Analog Module GE Fanuc Emerson | Learn More |

| IC695ALG306 | Isolated Thermocouple Input Module GE Fanuc Emerson | Learn More |

| IC695ALG312 | Thermocouple Input Module GE Fanuc Emerson | Learn More |

| IC695ALG412 | High Speed Thermocouple Module GE Fanuc Emerson | Learn More |

| IC695ALG508 | Isolated RTD Input Module GE Fanuc Emerson | Learn More |

| IC695ALG600 | Universal Analog Input Module GE Fanuc Emerson | Learn More |

| IC695ALG608 | Analog Input Module GE Fanuc Emerson | Learn More |

| IC695ALG616 | Analog Input Module GE Fanuc Emerson | Learn More |

| IC695ALG626 | GE Fanuc Emerson Analog Input Module | Learn More |

| IC695ALG628 | Analog Input Module GE Fanuc Emerson | Learn More |

No products in the cart.

No products in the cart.