ISA100 Wireless: Evolving Industrial Connectivity for Modern Applications

The International Society of Automation established the ISA100 Committee in 2005 to develop comprehensive standards for wireless systems in industrial automation environments. The resulting ISA-100.11a standard specifically addresses low-energy field device requirements for monitoring and process control applications where 100 ms latency tolerances are acceptable.

Proven Technology with International Recognition

ISA100 Wireless achieved ANSI approval in 2012 and international standardization as IEC 62734 in 2014. As the only IPv6 over 6LowPAN industrial protocol designed specifically for automation applications, the technology has demonstrated remarkable stability and maturity while maintaining consistent core protocols.

Industry Leadership Perspective

“ISA100 combines exceptional maturity with ongoing evolution that enhances rather than compromises the fundamental protocol,” stated Paul Hodge, Honeywell HPS global lead and ISA100 WCI vice chair. “Recent additions like Bluetooth Low Energy and OPC-UA provide valuable configuration and data access capabilities without altering the reliable core technology.”

Expanding Safety-Critical Applications

Recent advancements have significantly broadened ISA100’s application scope to include safety-critical functions. “Market acceptance of safety over wireless represents the primary evolution,” noted Ådne Baer-Olsen, Dräger’s global business development lead for wireless safety. “This technology now sees global implementation, offering substantial flexibility when combined with process control capabilities.”

Technical Advancements and Integration

Philippe Moock, former Armstrong International global director, highlighted several key developments: “Beyond BLE and OPC-UA support, PA-DIM integration represents a crucial advancement. Enhanced IPv6 incorporation at network and transport layers, along with improved cybersecurity, further strengthens the protocol’s capabilities.”

Safety System Implementation

“ISA100 Wireless has experienced growing safety application adoption over the past four to five years,” explained Robert Assimiti, Centero CEO. “The architecture inherently supports safety applications, with SIL2-certified field devices now deployed in mission-critical scenarios including gas detection, sounders, and beacon systems.”

Wireless Technology Landscape Analysis

The expanding array of industrial wireless technologies creates understandable market confusion. “Protocol abundance certainly presents challenges,” acknowledged Hodge. “ISA100 serves specific market segments, while alternatives like LoRa may better suit less demanding applications.”

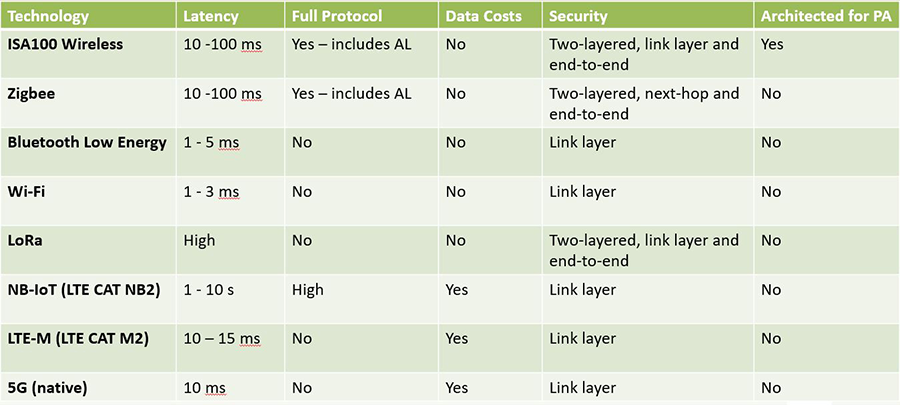

Figure 1: Comprehensive comparison of industrial IIoT wireless technologies.

Protocol Differentiation Challenges

“Market confusion persists regarding ISA100, WirelessHART, and other industrial wireless solutions,” Moock observed. “This stems from overlapping capabilities and varying industry adoption levels. Vendors often promote preferred standards without clearly explaining ecosystem integration strategies.”

Architectural Distinctions

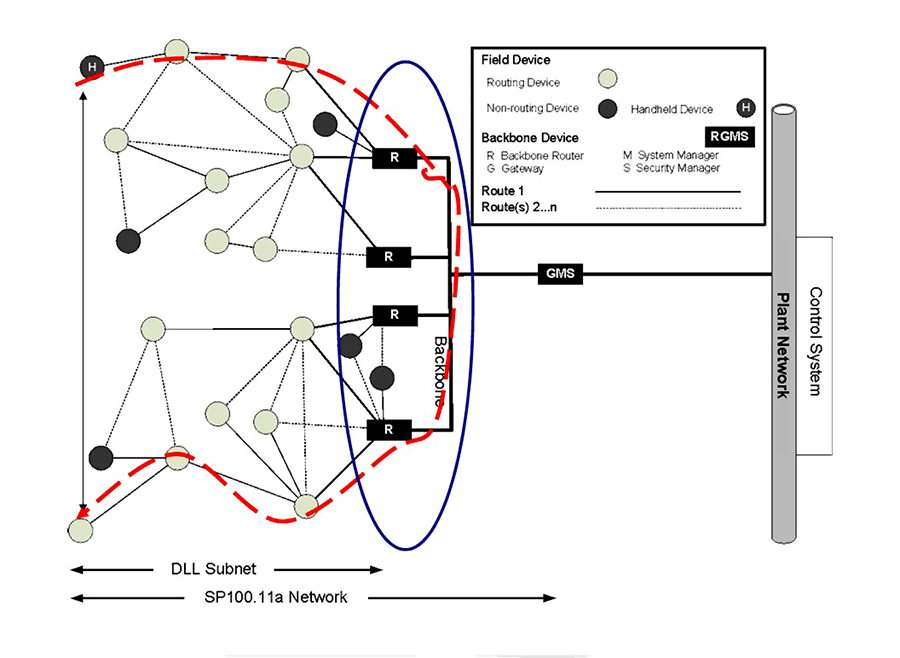

Baer-Olsen clarified fundamental differences: “While both ISA100 and WirelessHART operate at 2.4 GHz, ISA100’s ability to tunnel foreign protocols like Modbus, OPC, and Profinet/ProfiSafe provides superior flexibility and enables SIL2 safety communication. Combined with redundancy and latency control, this allows ProfiSafe-enabled controller integration.”

Figure 2: ISA100 network topology supporting multiple configuration types.

Figure 3: WirelessHART network topology comparison.

Complementary Technology Roles

Baer-Olsen further explained technology specializations: “LoRa offers exceptional range for monitoring applications with lower data requirements. Bluetooth serves device programming and edge data collection, while WirelessHART effectively handles non-time-critical messaging through mesh networking.”

Application-Specific Technology Selection

Assimiti emphasized context-dependent selection: “WirelessHART essentially represents wired HART over wireless, making it ideal for existing HART infrastructure. Selection primarily depends on installed DCS systems and client applications operating on plant networks.”

Comparative Technology Analysis

ISA100 Wireless Advantages:

– Superior flexibility for multi-protocol environments

– Enhanced architectural openness (mesh, duo cast, star)

– Strong IIoT system integration capabilities

– Mission-critical application suitability

Alternative Technology Applications:

– LoRa: Long-range environmental monitoring

– BLE: Device provisioning and short-range sensing

– Wi-Fi: High bandwidth non-deterministic applications

– 5G: Emerging industrial automation with private networks

Strategic Implementation Considerations

From my industrial networking experience, facilities should evaluate wireless technology selection based on latency requirements, existing infrastructure, safety certification needs, and long-term digital transformation strategies. ISA100 typically delivers optimal performance for mixed-protocol environments requiring deterministic communication.

Industrial Application Scenarios

Modern ISA100 implementations successfully support steam trap monitoring, pressure relief valve tracking, gas detection systems, and corrosion monitoring. The technology’s proven reliability in safety instrumented systems makes it particularly valuable for offshore and hazardous environment applications.

Future Development Trajectory

ISA100’s radio technology has significantly improved over 15 years of development, delivering substantially better performance than initial implementations. The standard’s forward-compatible design ensures continued relevance amid evolving industrial communication requirements.

Frequently Asked Questions

What distinguishes ISA100 from WirelessHART?

ISA100 offers greater protocol flexibility, foreign protocol tunneling capability, and deterministic latency control, while WirelessHART provides seamless integration with existing HART device ecosystems.

Can ISA100 support safety instrumented systems?

Yes, ISA100 supports SIL2-certified safety applications including gas detection, emergency signaling, and safety controller integration with proper network configuration.

How does ISA100 compare to LoRa technology?

ISA100 provides deterministic, real-time communication for control applications, while LoRa offers long-range, low-power connectivity suitable for non-critical monitoring.

What integration capabilities does ISA100 offer?

ISA100 supports OPC-UA, Bluetooth Low Energy for configuration, PA-DIM, and multiple industrial protocols including Modbus and Profinet through tunneling.

Is ISA100 suitable for battery-powered devices?

Yes, ISA100 efficiently supports low-energy field devices with optimized power consumption for extended battery life in monitoring applications.

No products in the cart.

No products in the cart.