Modernizing Oil and Gas Operations: Heritage Petroleum’s SCADA Transformation

Company Background and Operational Challenges

Following Petrotrin’s restructuring in 2018, Heritage Petroleum Company emerged as Trinidad and Tobago’s new state oil enterprise. The company manages both onshore and offshore exploration and production operations. However, their inherited SCADA infrastructure required substantial improvements. The system needed digital transformation and IoT integration to meet modern industrial automation standards.

Strategic Project Development Approach

TOSL Automation and Technology Limited assembled a specialized team to lead this initiative. General Manager Keone Jackman and ICE Engineer Aneesa Mohammed directed the project. They partnered with Costa Rican firms Incentro S.A. and Soati for software support and system integration. This collaboration proved crucial for the project’s success.

Two-Phase Implementation Strategy

The modernization program followed a structured two-phase approach. Phase one focused on upgrading existing AVEVA InTouch, Historian and Web Client systems. The team identified significant cost savings by leveraging current equipment rather than complete replacement. This strategic decision preserved capital while achieving performance goals.

Expanding Capabilities with IoT Integration

Phase two substantially broadened the project scope. Heritage sought to incorporate electrical substations, compression monitoring and remote sensors using MQTT protocol. This expansion created demand for a robust MQTT Broker solution. Skkynet’s DataHub software emerged as the ideal choice due to its MQTT support and AVEVA compatibility.

Technical Implementation and Data Flow

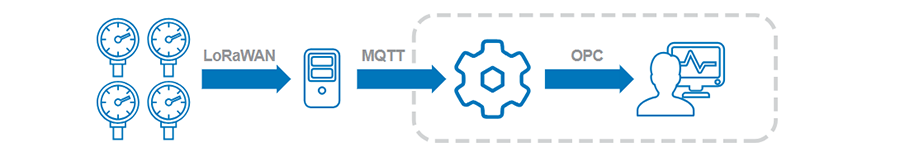

The installation team deployed HiberHilo sensors across offshore production facilities. These sensors transmitted data streams to a LoRaWAN network server. TATL engineers connected this server to DataHub as an MQTT client. The DataHub MQTT Smart Broker then collected and integrated multiple data streams. Finally, it transmitted processed information via OPC to AVEVA applications.

Overcoming Interface and Protocol Challenges

This project presented unique interface design obstacles. The team manually selected specific data points for InTouch display. They created custom tags and developed screens from initial concepts. Multiple JSON formats from various sensors required sophisticated processing. Skkynet’s support team developed custom conversion scripts to handle this complexity.

Building System Redundancy and Reliability

The project encountered unexpected server connectivity limitations. HiberHilo servers couldn’t support the planned parallel connection configuration. Through collaborative problem-solving with Soati, Incentro and Skkynet, the team devised an innovative solution. They implemented quality-of-service monitoring with automatic failover switching between MQTT servers.

Achieving Operational Excellence and Cost Efficiency

The implemented solution delivered substantial benefits. Heritage gained modernized dashboards and improved system availability. User experience enhanced through better interface design and stability. The MQTT connections enabled advanced analytics and superior alarm management. Most importantly, reusing existing infrastructure saved approximately six months of implementation time.

Knowledge Transfer and Ongoing Support

Skkynet provided comprehensive training sessions for Heritage’s IT department. These focused on DataHub scripting and new device integration. The support team demonstrated exceptional responsiveness, typically delivering script modifications within 24-48 hours. Their consistent availability for troubleshooting ensured project success.

Industry Perspective: The Value of Flexible Solutions

This case demonstrates how adaptable industrial automation solutions create significant value. Rather than wholesale system replacement, strategic upgrades can extend equipment lifespan while adding modern capabilities. The DataHub platform’s flexibility enabled customized problem-solving that off-the-shelf solutions couldn’t provide. This approach represents industry best practice for digital transformation projects.

Future Expansion Plans

Heritage plans additional implementations across onshore business units. The roadmap includes integrating more sensors and developing additional InTouch monitoring screens. TATL remains prepared to support these expansions with further DataHub installations and custom scripting as needed.

Application Scenario: Industrial IoT Implementation

This project exemplifies effective Industrial IoT deployment in challenging environments. Offshore oil production facilities demand robust, secure data communication. The solution combines LoRaWAN networking with MQTT protocol and OPC integration. This architecture provides a template for similar industrial automation upgrades across energy sector operations.

About Skkynet

Skkynet leads globally in real-time data communication software and services. Their solutions enable secure data acquisition, monitoring and consolidation for industrial applications. The DataHub product family ensures reliable connectivity for industrial automation, IIoT and Industry 4.0 implementations. Visit skkynet.com for company information and cogentdatahub.com for product details.

Download the PDF Version

Frequently Asked Questions

What challenges did Heritage Petroleum face with their original SCADA system?

Heritage inherited an outdated SCADA infrastructure requiring digital transformation. The system lacked modern IoT capabilities and needed improved data visibility for production monitoring and ERP integration.

How did the project team achieve cost savings during implementation?

Rather than complete system replacement, the team upgraded existing AVEVA software and reused communication infrastructure. This approach saved approximately six months of implementation time and substantial capital investment.

What role did Skkynet’s DataHub play in the solution?

DataHub served as an MQTT Smart Broker, integrating sensor data from HiberHilo devices and transmitting it to AVEVA applications. It also handled JSON format conversions and provided system redundancy.

How was the system redundancy challenge resolved?

The team implemented quality-of-service monitoring with automatic failover. DataHub scripts continuously assess data path quality and switch between MQTT servers when signal quality deteriorates.

What ongoing support did Skkynet provide after implementation?

Skkynet conducted knowledge transfer sessions and provided responsive technical support. Their team typically delivered script modifications within 24-48 hours and remained available for troubleshooting.

No products in the cart.

No products in the cart.