A Practical Guide to GE Series 90-30 Analog Input Modules

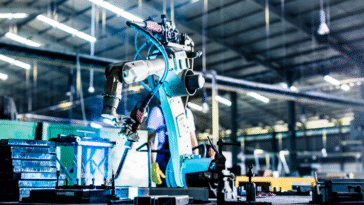

Analog input modules bridge physical processes and digital control systems. They convert continuous signals from field sensors into data the PLC can use. This conversion is fundamental for precise monitoring and control in industrial automation.

Detailed Comparison of Five Key Models

The IC693ACC303 handles eight standard 0-10V DC voltage inputs. In contrast, the IC693ACC307 accepts eight 4-20mA current signals, which are dominant in process control. For higher density, the IC693ACC310 provides sixteen voltage input channels. Furthermore, the IC693ACC317 is a dedicated 8-channel thermocouple input card. The IC693ACC323 suits various millivolt and voltage sensors, offering greater range flexibility.

How Signal Conversion and Isolation Work

These modules perform Analog-to-Digital Conversion (ADC) internally. They sample the incoming signal and translate it into a binary number. More importantly, they provide channel-to-backplane isolation. This isolation prevents electrical noise on the factory floor from disrupting the sensitive PLC system.

Matching Modules to Real-World Applications

Selecting the correct module depends on your sensor outputs. Use the ACC307 for 4-20mA devices like pressure transmitters. The ACC303 is ideal for simple voltage-output sensors. Deploy the ACC317 for direct J or K-type thermocouple connections without external transmitters. This precise matching ensures system accuracy and reduces integration costs.

Author’s Perspective on Legacy System Support

While newer PLCs offer integrated analog I/O, countless 90-30 racks remain operational. Understanding these modules is key for maintenance and legacy system expansion. My experience shows that stocking the correct spare module, often the ACC307, minimizes production downtime. However, for new projects, evaluate modern alternatives with higher resolution and Ethernet connectivity.

Application Scenario: Temperature Monitoring System

A common solution involves using an IC693ACC317 module. It directly connects multiple thermocouples from ovens or tanks to the PLC. The module’s built-in cold-junction compensation ensures accurate readings. The PLC logic then monitors these temperatures and triggers cooling fans or alarms, creating a reliable and standalone control loop.

Frequently Asked Questions

Q1: What is the main difference between IC693ACC303 and IC693ACC307?

The ACC303 accepts voltage inputs (0-10V), while the ACC307 accepts current inputs (4-20mA). The 4-20mA standard is more noise-resistant for long-distance wiring in factory automation.

Q2: Can the IC693ACC310 module measure current signals?

No, the ACC310 is designed for voltage inputs only. For current signals with the 90-30 PLC, you must select the ACC307 module or use an external signal converter.

Q3: Which module should I use for thermocouples?

The IC693ACC317 is specifically designed for thermocouple inputs. It supports multiple thermocouple types and handles necessary cold-junction compensation internally.

Q4: Are these GE Fanuc modules still available for purchase?

Yes, but they are often considered legacy stock. You can source them from authorized Emerson distributors or reliable industrial automation parts suppliers.

Q5: How do I configure these modules in the PLC programming software?

You configure the modules in the PLC hardware configuration layout. This setup defines the module type and its starting address in the PLC’s input register table for data mapping.

No products in the cart.

No products in the cart.