A Practical Guide to Selecting GE PACSystems RX3i Controllers

Understanding Five Core Processor Models for Machine and Process Control

Navigating Modern Control System Choices

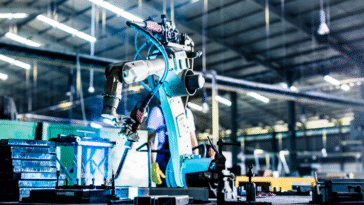

Industrial facilities need reliable automation solutions. GE’s PACSystems RX3i series provides powerful programmable controllers. These systems bridge PLCs and larger DCS solutions. This guide explores five key CPU models for engineers.

The Foundation of PAC Operation

These controllers execute control logic in real-time. They read inputs, run programs, then update outputs. The Proficy Machine Edition software programs all models. This standardization helps factory automation projects.

Model IC695CPE302: Compact and Economical

The CPE302 offers basic control with 90 MHz processing. It suits simple machine control applications. However, its limited memory restricts complex tasks. Therefore, use it for small-scale projects.

Model IC695CPE305: Reliable Mid-Tier Performer

This model provides 300 MHz processing power. It handles moderate process control well. Moreover, it manages data logging effectively. Many machine builders choose this balanced option.

Model IC695CPE310: Optimized for Data Integration

The CPE310 features 1 GHz speed for data tasks. It connects well with HMIs and networks. Consequently, it fits supervisory control scenarios. Data-intensive applications benefit most.

Model IC695CPE330: Engineered for Precision

This CPU specializes in high-speed control. Its separate coprocessor enables precise motion control. Packaging and metals industries often select it. The deterministic performance ensures quality.

Model IC695CPE400: Maximum Power for Critical Systems

The flagship model delivers top performance. It supports large distributed control systems. Mission-critical operations require this reliability. Infrastructure projects typically need this power.

How to Choose the Correct CPU for Your Project

Consider processing speed and memory first. Evaluate application complexity second. Analyze communication requirements third. Finally, plan for future expansion needs. This approach prevents costly mistakes.

Application Scenarios and Solutions

Water Treatment: Use CPE310 for process control and data logging.

Packaging Line: Select CPE330 for synchronized motion control.

Assembly System: Choose CPE305 for general automation tasks.

Power Plant: Implement CPE400 for critical control systems.

Author’s Perspective on Industry Trends

Modern automation demands data capabilities. The CPE310 addresses this need effectively. Always test worst-case scan times during design. Planning for expansion protects investments long-term.

Concluding Recommendations for System Integrators

Match CPU capabilities to application needs. Start with CPE302 for simple control. Use CPE305 for most machines. Select CPE310 for data tasks. Choose CPE330 for precision motion. Reserve CPE400 for largest systems.

Frequently Asked Questions

Q1: What software programs these controllers?

A: All use Proficy Machine Edition software from GE.

Q2: Can I upgrade from one CPU to another?

A: Yes, within the same backplane with proper planning.

Q3: Which CPU handles Ethernet communication best?

A: The CPE310 and higher models manage network traffic effectively.

Q4: How do I calculate required memory?

A: Estimate program size plus 50% for future modifications.

Q5: What industries use these controllers?

A: Manufacturing, energy, water treatment, and transportation sectors.

No products in the cart.

No products in the cart.