Mastering GE Fanuc 90-30 PLC Modules: A Technical Deep Dive

Understanding the Legacy of GE Fanuc 90-30 Systems

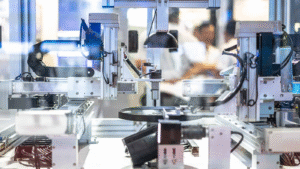

GE Fanuc’s Series 90-30 PLC remains a cornerstone in factory automation. Many facilities still rely on this robust control system. Its modular I/O components are crucial for system performance. Understanding these modules ensures optimal operation and maintenance.

IC693ALG391: High-Density Analog Input Solution

This module handles sixteen single-ended analog signals. It converts voltage or current inputs into digital data. Therefore, it is perfect for monitoring multiple process variables. Applications include temperature sensing and pressure monitoring across various zones.

IC693ALG392: Isolated Channel Analog Input Module

The ALG392 provides eight isolated analog input channels. This design prevents electrical noise interference between signals. Consequently, it delivers superior signal integrity in harsh industrial environments with heavy machinery.

IC693ALG442: Precision Analog Output Control

This four-channel output module drives field devices like valve positioners and VFDs. It translates digital commands from the CPU into precise analog signals. As a result, it enables accurate speed and process control in automated systems.

IC693APU300 & APU301: System Power Core Units

These power supply modules convert incoming AC or DC to backplane power. The APU300 accepts 120/240V AC input. Conversely, the APU301 operates from a 24V DC source. They form the foundational power core for the entire PLC rack.

Practical Selection Guide for Engineers

Choose ALG391 for cost-effective, high-channel-count applications in clean electrical areas. However, select ALG392 for critical measurements in electrically noisy plants. The ALG442 is essential for control output commands. Your available power source dictates the choice between APU300 and APU301.

Real-World Application Scenarios

A water treatment plant uses ALG391 to monitor filter pressures. A automotive assembly line employs ALG392 for critical weld controller feedback. Furthermore, a chemical processor utilizes ALG442 to control mixing valve actuators. The APU301 often supports DC-powered safety systems.

Expert Commentary on Modern Relevance

While newer PAC systems exist, the 90-30 series maintains a vast installed base. Sourcing these modules for legacy systems is a common challenge. Proper grounding remains critical for analog signal accuracy. We recommend auditing spare parts for aging systems.

Frequently Asked Questions (FAQ)

Q1: Can I mix ALG391 and ALG392 modules in the same PLC rack?

Yes, the backplane supports mixing different analog modules. You must configure each module’s type in the PLC hardware configuration software correctly.

Q2: What is the main advantage of channel isolation in the ALG392?

Isolation protects against ground loops and noise. It ensures a fault on one channel does not disrupt measurements on adjacent channels.

Q3: Is the IC693ALG442 module capable of sourcing enough power for a motor drive?

No. The ALG442 provides a command signal (e.g., 4-20mA or 0-10V). The motor drive itself requires a separate, high-power supply to operate the motor.

Q4: Can the IC693APU301 power the entire rack from a standard UPS?

Yes. Its 24V DC input makes it highly compatible with many Uninterruptible Power Supply systems designed for control panels.

Q5: Are these GE Fanuc 90-30 modules still available for purchase new?

They are considered legacy products. Availability of new units is limited. However, several specialized industrial automation suppliers stock refurbished and tested units.

No products in the cart.

No products in the cart.