Understanding GE Fanuc 90-30 PLC I/O Modules: A Technical Selection Guide

Introduction to the Legacy GE Fanuc 90-30 PLC System

Many operational factories rely on the robust GE Fanuc Series 90-30 programmable logic controller. This system forms the backbone for numerous industrial automation applications. Its flexible I/O module selection allows precise control system customization. This guide clarifies five essential I/O modules for engineers. Proper selection ensures system longevity and performance.

Detailed Module Functions and Specifications

Each module addresses specific interface needs within a PLC chassis. The IC697MDL252 handles sixteen channels of 24V DC input signals. The IC697MDL253 controls sixteen channels of 24V DC output. For combined needs, the IC697MDL254 offers eight inputs and eight outputs. Conversely, the IC697MDL340 processes analog input signals like 4-20mA. The IC697MDL341 generates analog output commands for field devices.

How These Modules Operate in a Control System

Digital modules manage simple on/off states for devices like limit switches. They send and receive signals to execute discrete logic within the PLC CPU. Analog modules translate continuous process variables. The MDL340 digitizes sensor readings for CPU analysis. Therefore, the MDL341 executes precise control by converting digital commands to analog signals.

Common Application Scenarios in Industry

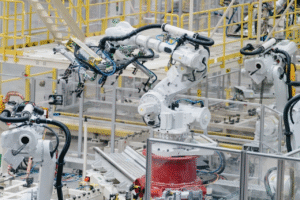

You will find digital I/O modules in high-speed discrete manufacturing. Typical uses include robotic cell interlocks and conveyor sequencing. Analog modules are critical for process industries. They manage variables such as tank levels, temperature loops, and pressure setpoints in DCS-influenced systems.

Key Factors for Module Selection and Comparison

Your signal type dictates the primary choice between digital and analog modules. Consider point density and mixing requirements when selecting the MDL254. For analog modules, always verify signal range and resolution. Furthermore, assess the module’s compatibility with your existing Series 90-30 CPU and backplane.

Author’s Perspective on Legacy System Support

In my experience, these modules demonstrate remarkable field reliability. Their sustained demand highlights a key industry challenge: maintaining legacy control systems. While modern PACs offer advanced features, a wholesale upgrade is often impractical. Consequently, understanding these modules is crucial for cost-effective plant maintenance and lifecycle management.

Practical Solution Scenario: Batch Process Upgrade

A chemical plant needed to upgrade a batching system without replacing the entire GE Fanuc 90-30 PLC. Engineers added two IC697MDL340 modules to integrate new smart flowmeters. They also used one IC697MDL341 to control a proportional valve. This solution improved accuracy while leveraging the stable, existing control hardware, showcasing a practical retrofit approach.

Frequently Asked Questions (FAQ)

Q1: Can I mix IC697MDL252 and IC697MDL253 modules in the same rack?

Yes, absolutely. The GE Fanuc 90-30 platform allows flexible mixing of digital input and output modules within the same chassis to match your application’s exact I/O count requirements.

Q2: What is the main difference between the MDL340 and MDL341 modules?

The IC697MDL340 is an Analog Input module for reading signals from sensors. The IC697MDL341 is an Analog Output module for sending command signals to control devices like valve positioners or variable speed drives.

Q3: How do I configure the analog signal range on the MDL340/MDL341?

Configuration is performed via software in the PLC programming environment (such as Proficy Machine Edition). You set the voltage or current range (e.g., 0-10V, 4-20mA) through the hardware configuration settings for the module’s channel.

Q4: Why would I choose the mixed I/O MDL254 module?

The IC697MDL254 optimizes rack space and reduces part numbers when you need a balanced combination of discrete inputs and outputs in one location, simplifying logistics and installation.

No products in the cart.

No products in the cart.