GE Fanuc IC200CHS Hot Swap Modules: A Guide to Uninterrupted Control

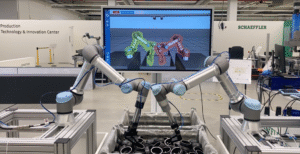

Understanding Hot Swap Capability in PLC Systems

Hot swap modules let technicians replace components during operation. They manage power distribution to the PLC backplane. This process prevents system crashes during maintenance. Therefore, production lines can continue running without expensive stops. These modules are vital for high-availability systems.

Core Functions of the IC200CHS Series

The IC200CHS series serves the VersaMax PLC platform. Its primary role is ensuring system integrity during module changes. Moreover, specific models provide power redundancy and memory backup. This functionality is crucial for complex industrial control systems in manufacturing.

Comparing the IC200CHS001, 002, and 003 Models

Each model offers distinct features for different needs. The IC200CHS001 delivers essential hot-swap functionality. The IC200CHS002 adds a battery backup for memory retention. The IC200CHS003 supports dual power supplies for maximum reliability. Consequently, selecting the right model depends on your application’s criticality.

Key Applications for Hot Swap Modules

These modules excel in continuous process industries. Chemical plants and power generation facilities rely on them. They are also essential in automotive and pharmaceutical manufacturing. Any unplanned downtime in these sectors results in significant financial loss.

Selecting the Right Module for Your Application

Your choice should balance cost against operational risk. Use the IC200CHS001 for non-critical applications. Choose the IC200CHS002 for processes requiring data integrity. Opt for the IC200CHS003 in environments with unstable power. This strategic selection enhances your overall factory automation resilience.

Author’s Insight

In practice, the IC200CHS003’s dual-power feature often proves most valuable. The initial higher cost is negligible compared to the expense of a single production halt caused by a power supply failure. Proactive investment in redundancy is a hallmark of mature automation system design.

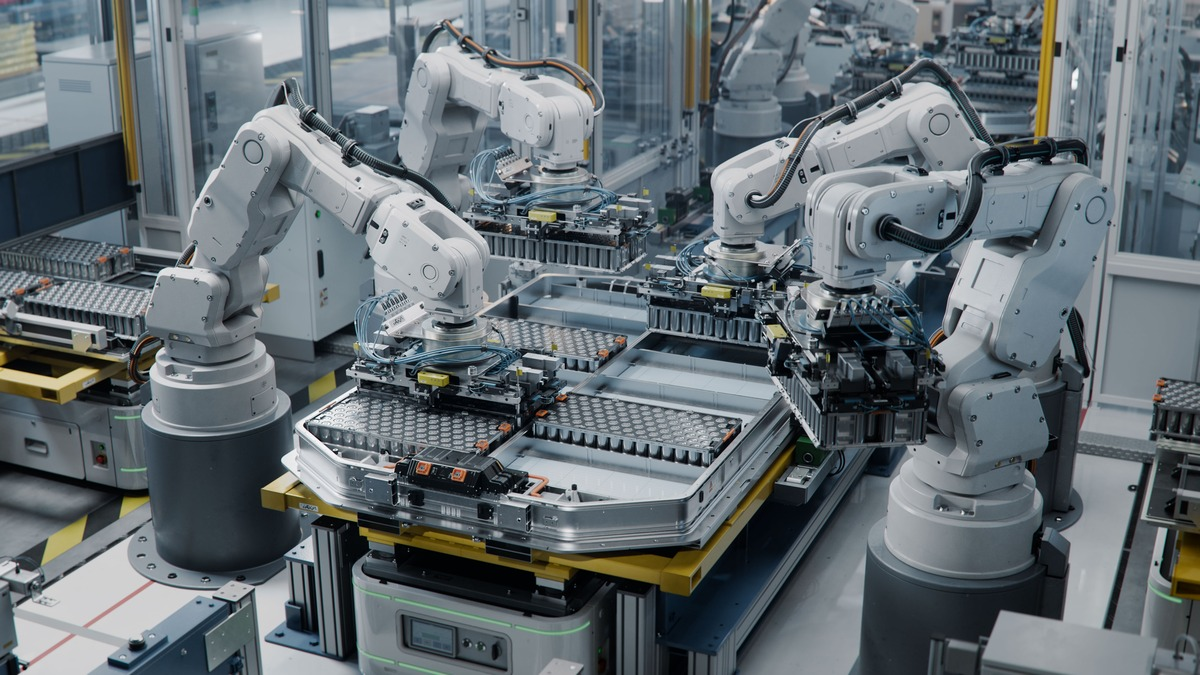

Practical Solutions and Use Case Scenarios

- Scenario 1: Automotive Assembly Line. An IC200CHS003 module allows engineers to replace a faulty digital input module during a shift change. The line continues operating, saving thousands in lost production.

- Scenario 2: Batch Chemical Processing. Using an IC200CHS002, a plant maintains its recipe data during a brief power fluctuation. This prevents the loss of an entire batch, ensuring product quality and saving raw materials.

Frequently Asked Questions (FAQ)

Q1: Can I use an IC200CHS001 in a safety-critical system?

A1: For basic I/O, yes. However, for certified safety systems, always use components specified in the safety system’s manual.

Q2: What is the main advantage of the IC200CHS003?

A2: Its support for two isolated power supplies. This eliminates a single point of failure, greatly boosting DCS reliability.

Q3: Are these modules compatible with newer RX3i systems?

A3: No, the IC200CHS series is designed for the VersaMax platform. Emerson’s newer systems use different hardware architectures.

Q4: Do I need a special procedure for hot swapping?

A4: Yes. Always follow the manufacturer’s guidelines. This typically involves unlocking the module and waiting for an indicator before removal.

Q5: How does hot swapping improve plant efficiency?

A5: It enables proactive and scheduled maintenance without stopping the entire control system, maximizing overall equipment effectiveness (OEE).

No products in the cart.

No products in the cart.