Chemical Etching Powers Clean Energy Innovation Across Industries

The Unsung Hero of Modern Manufacturing

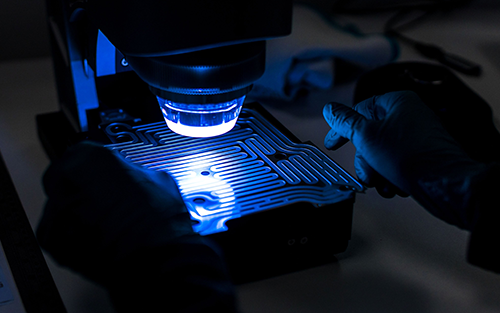

Chemical etching emerges as a critical manufacturing technology for clean energy solutions. This precise metal fabrication method enables complex component production. It supports advancements across electric vehicles, aerospace, and hydrogen systems. The technology’s flexibility makes it ideal for evolving energy applications.

Space Exploration Demands Precision

Satellite and space mission components require extreme precision and reliability. Chemical etching produces stress-free nickel interconnects for space batteries. These components withstand harsh deep-space environments. The process allows rapid design changes without expensive tooling modifications.

Aerospace Thermal Management Solutions

Advanced heat exchangers rely on chemically etched aluminum plates. These components manage critical cooling systems in aircraft engines. The technology now supports hydrogen fuel cell development. Etched bipolar plates enable more efficient energy conversion in next-generation aircraft.

Ground Transportation Evolution

Electric and hydrogen vehicles both benefit from etching technology. The manufacturing process creates essential busbars and fuel cell components. Recent studies show hydrogen vehicles may achieve superior emissions reduction. Different technologies will likely coexist based on application requirements.

Autonomous Vehicle Integration

Self-driving vehicles utilize etched copper busbars in battery systems. These components feature safety breakpoints to prevent complete system failures. Chemical etching supports moderate-volume production during development phases. The technology enables quick adaptation to evolving design specifications.

Cross-Industry Technology Convergence

Energy system innovation drives manufacturing process unification. Chemical etching serves multiple sectors with similar precision requirements. The technology supports rapid prototyping and production across materials. This convergence reflects broader clean energy transformation trends.

Manufacturing Advantages

Chemical etching offers distinct benefits over traditional methods. It eliminates mechanical stresses associated with stamping processes. Design modifications require minimal tooling adjustments. The process maintains precision across various metals and applications.

Future Applications and Potential

The technology continues finding new clean energy applications. Hydrogen production equipment increasingly incorporates etched components. Space technology innovations often transfer to terrestrial applications. Manufacturing flexibility ensures ongoing relevance across evolving sectors.

Frequently Asked Questions

What makes chemical etching suitable for space applications?

It produces stress-free, high-precision components that withstand extreme environments while allowing rapid design iterations.

How does etching support hydrogen technology development?

It creates precise bipolar plates for fuel cells and heat exchanger components for hydrogen production systems.

Why is etching preferred for electric vehicle components?

The process enables complex busbar designs with safety features and accommodates evolving specifications during development.

Can etching handle different materials?

Yes, it works with various metals including nickel, copper, aluminum and specialized alloys for different applications.

How does etching compare to stamping and laser cutting?

It offers greater design flexibility, eliminates mechanical stress, and requires lower tooling costs for complex components.

No products in the cart.

No products in the cart.